The fuel delivery industry is facing mounting pressure to reduce operational costs while meeting increasingly high customer expectations for speed and reliability. Fuel delivery route optimization has emerged as a critical solution, with companies implementing sophisticated systems that can reduce fuel costs by up to 30% and improve delivery efficiency by 25%. As fuel prices fluctuate and driver shortages persist across North America, real-time route optimization technology has transitioned from a competitive advantage to an operational necessity.

In 2024, the global route optimization software market reached $5.87 billion and is projected to grow at a CAGR of 11.3% through 2030, according to Grand View Research. This growth reflects the increasing complexity of last-mile logistics and the urgent need for intelligent systems that can adapt to changing conditions in real-time.

Understanding Real-Time Route Optimization for Fuel Delivery

Real-time route optimization represents a significant evolution from traditional static routing systems. Unlike conventional approaches that calculate routes once at the start of a shift, real-time systems continuously analyze multiple variables, such as traffic patterns, delivery priorities, vehicle capacity, driver hours, weather conditions, and customer time windows, to dynamically adjust routes as conditions change throughout the day.

For fuel delivery operations specifically, this technology addresses unique challenges: hazardous material regulations, varying tank capacities at customer sites, emergency delivery requests, and the critical nature of fuel shortages for commercial clients. A sophisticated route optimization platform must balance these factors while maintaining safety standards and regulatory compliance.

The Core Components of Route Optimization Systems

Modern fuel delivery logistics optimization systems integrate several critical components:

GPS and Telematics Infrastructure: Real-time vehicle tracking provides the foundation for dynamic routing. Modern GPS systems offer accuracy within 3-5 meters and update vehicle positions every 10-30 seconds, enabling precise arrival time predictions and immediate response to delays.

Predictive Analytics Engine: Machine learning algorithms analyze historical delivery data, traffic patterns, and seasonal variations to predict optimal routes. These systems can process thousands of potential route combinations per second, identifying solutions that human dispatchers would miss.

Dynamic Constraint Management: The system must continuously evaluate and respect multiple constraints—driver working hours (HOS compliance), vehicle capacity limits, customer delivery windows, fuel type compatibility, and road restrictions for hazardous materials.

Integration Layer: Seamless connections with existing business systems, including order management, inventory control, customer relationship management (CRM), and accounting platforms, ensure data consistency across operations.

Route Optimization Impact: Before vs. After Implementation

| Performance Metric | Before Optimization | After Optimization | Improvement |

| Average Miles per Vehicle per Day | 165 miles | 129 miles | 22% reduction |

| On-Time Delivery Rate | 78% | 92% | 18% improvement |

| Deliveries per Driver per Day | 12 deliveries | 15 deliveries | 25% increase |

| Route Planning Time (Daily) | 2-3 hours | 20-30 minutes | 85% reduction |

| Fuel Cost per Delivery | $29 | $22 | 24% savings |

| Overtime Hours per Week | 45 hours | 18 hours | 60% reduction |

Technologies Powering Modern Route Optimization

Algorithmic Approaches and Their Trade-offs

The heart of any fuel delivery logistics optimization system lies in its routing algorithms. Several approaches exist, each with distinct advantages and limitations:

Genetic Algorithms: These evolutionary computation methods simulate natural selection to find optimal routes. They excel at handling complex, multi-variable problems and can escape local optima that trap simpler algorithms. However, they require significant computational resources and may take longer to converge on solutions—typically 5-15 seconds for a fleet of 20-30 vehicles.

Ant Colony Optimization: Inspired by the foraging behavior of ants, these algorithms build solutions iteratively by simulating pheromone trails. They perform particularly well for dynamic routing problems where routes need frequent recalculation. The approach typically achieves 90-95% of optimal solutions while maintaining fast computation times of 2-5 seconds.

Simulated Annealing: This probabilistic technique explores the solution space by occasionally accepting worse solutions to escape local optima. It’s computationally efficient but may struggle with highly constrained problems common in fuel delivery—such as strict delivery windows combined with multiple fuel type requirements.

Hybrid Approaches: Modern commercial systems often combine multiple algorithms. A typical implementation might use Clarke-Wright savings algorithm for initial route construction, then refine with 2-opt or 3-opt local search heuristics, achieving near-optimal solutions in under 3 seconds for fleets up to 50 vehicles.

Routing Algorithm Comparison

| Algorithm Type | Computation Time | Solution Quality | Best Use Case | Complexity Level |

| Genetic Algorithms | 5-15 seconds | 95-98% optimal | Complex multi-constraint problems | High |

| Ant Colony Optimization | 2-5 seconds | 90-95% optimal | Dynamic routing with frequent changes | Medium-High |

| Simulated Annealing | 1-3 seconds | 85-92% optimal | Time-sensitive routing decisions | Medium |

| Clarke-Wright Savings | <1 second | 75-85% optimal | Initial route construction | Low |

| 2-opt/3-opt Local Search | 1-2 seconds | 88-93% optimal | Route refinement and improvement | Medium |

| Hybrid Approaches | 2-4 seconds | 93-97% optimal | Production systems balancing speed and quality | Medium-High |

Cloud Infrastructure vs. Edge Computing

Architecture decisions significantly impact system performance, cost, and reliability. Cloud-based route optimization offers scalability and centralized management but requires constant connectivity. Edge computing approaches process data locally on vehicles or dispatch terminals, providing resilience during connectivity issues but with higher hardware costs.

A hybrid architecture often provides the best balance: critical real-time adjustments processed at the edge, with comprehensive optimization and analytics in the cloud. This approach ensures delivery operations continue even during network outages while maintaining the benefits of centralized intelligence and updates.

Mobile and Web Technologies

The front-end technology stack determines driver adoption and dispatcher efficiency. Delivery app route planning interfaces must balance functionality with simplicity, providing drivers with clear directions while enabling quick communication with dispatch.

React Native has become increasingly popular for fuel delivery applications due to its cross-platform capabilities and native performance. Organizations looking to implement robust routing interfaces often hire React Native app developers who understand both the technical requirements and the operational realities of delivery logistics.

Web-based dispatcher consoles typically leverage modern frameworks like React or Vue.js, enabling real-time updates through WebSocket connections. These interfaces must display complex information, current vehicle locations, pending orders, route visualizations, and performance metrics, in an intuitive format that supports rapid decision-making.

Implementation Considerations and Trade-offs

Data Quality and Integration Challenges

The accuracy of route optimization depends fundamentally on data quality. Incomplete or inaccurate address geocoding can derail even the most sophisticated algorithms. Studies show that poor data quality costs companies an average of $12.9 million annually, according to Gartner.

Address standardization and validation should occur at order entry, with automated geocoding services (Google Maps API, Here Technologies, or Mapbox) converting addresses to precise coordinates. For fuel delivery, additional verification of site accessibility for tanker trucks, including road width restrictions, height clearances, and turning radius requirements, prevents routing failures.

Integration with existing enterprise systems presents another significant challenge. Legacy dispatch systems may lack modern APIs, requiring custom middleware or data synchronization solutions. A phased implementation approach, starting with route optimization as a standalone system and gradually deepening integration, often reduces risk and accelerates time-to-value.

Balancing Optimization Objectives

Route optimization involves inherent trade-offs between competing objectives:

- Cost vs. Speed: The fastest routes often involve highways with tolls, while the cheapest routes take longer

- Efficiency vs. Flexibility: Tightly optimized routes become brittle when disruptions occur

- Fairness vs. Optimization: Perfectly optimized routes may consistently assign difficult deliveries to certain drivers

- Current Optimization vs. Future Positioning: The optimal route for today’s deliveries might leave vehicles poorly positioned for tomorrow’s expected orders

Advanced systems use multi-objective optimization algorithms that allow operators to adjust priority weights based on current business needs. During peak demand periods, speed might take precedence; during slower periods, cost reduction becomes paramount.

Real-World Performance Metrics

Companies implementing comprehensive route optimization systems typically observe:

- 15-30% reduction in total miles driven: Translating directly to fuel cost savings and reduced vehicle wear

- 20-35% improvement in on-time delivery performance: Meeting customer time windows more consistently

- 25-40% increase in deliveries per driver per day: Enabling fleet consolidation or volume growth without proportional fleet expansion

- 40-60% reduction in route planning time: Freeing dispatchers to focus on customer service and exception handling

These improvements compound over time as machine learning algorithms refine their predictions based on actual delivery performance data.

Building vs. Buying: Strategic Considerations

Organizations face a critical decision between developing custom route optimization capabilities or implementing commercial solutions. This choice depends on several factors:

When to Build Custom Solutions

Custom development makes sense when:

- Unique operational requirements cannot be addressed by commercial products (e.g., specialized fuel types, complex regulatory requirements specific to certain jurisdictions)

- Competitive differentiation depends on proprietary routing logic that provides a measurable market advantage

- Long-term total cost of ownership favors custom development over recurring licensing fees (typically for fleets exceeding 200 vehicles)

- Existing technical capabilities include experienced developers and infrastructure that can support ongoing maintenance

Organizations pursuing custom development should partner with a custom software development agency experienced in logistics optimization to avoid common pitfalls and accelerate development cycles.

When Commercial Solutions Excel

Commercial route optimization platforms offer advantages, including:

- Faster implementation: 2-4 months vs. 12-24 months for custom development

- Lower initial investment: $50,000-$200,000 vs. $500,000-$2,000,000+ for custom solutions

- Continuous improvement: Vendors invest in algorithm refinement, new features, and integration with emerging technologies

- Reduced technical risk: Proven solutions with established support infrastructure

Leading platforms like Route4Me, OptimoRoute, and Workwave include pre-built integrations with common telematics providers and business systems, significantly reducing implementation complexity.

Technical Architecture for Fuel Delivery Route Optimization

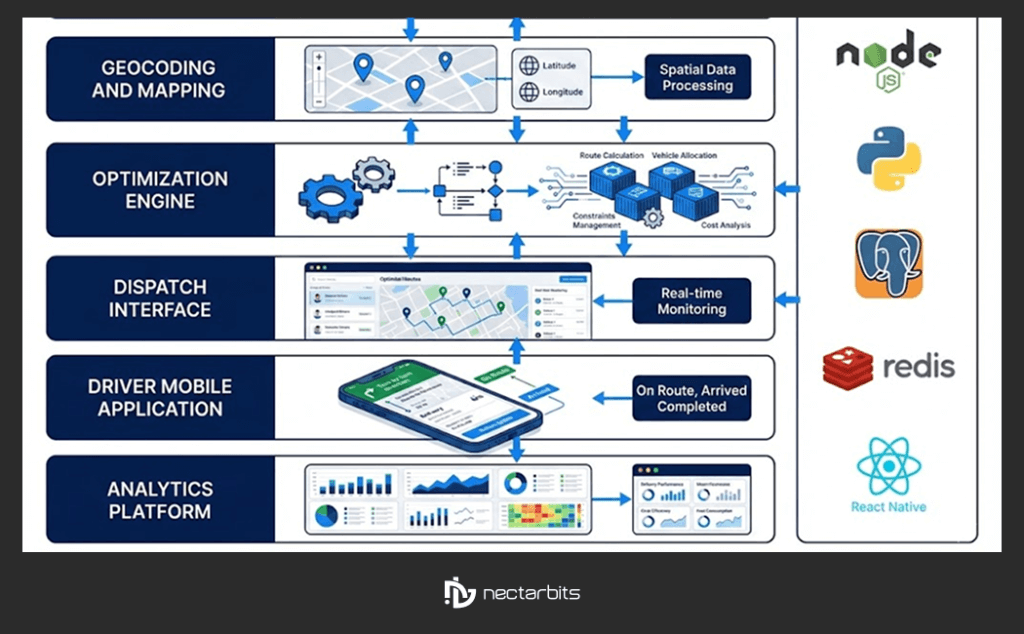

System Components and Data Flow

A complete route optimization system for fuel delivery includes several interconnected components:

Order Management Layer: Captures delivery requests with complete details—fuel type, quantity, delivery location, time windows, special instructions, and priority level. This layer validates order data and checks for conflicts or duplicate requests.

Geocoding and Mapping Services: Converts delivery addresses to precise coordinates and validates site accessibility. Advanced implementations include custom mapping layers showing fuel-specific information like tank truck access points, hazmat route restrictions, and prohibited areas.

Optimization Engine: The core algorithmic component that generates optimal routes considering all constraints and objectives. This typically runs as a microservice that can scale independently based on computational demands.

Dispatch Interface: Provides human oversight and intervention capabilities, allowing dispatchers to manually adjust routes when necessary, communicate with drivers, and monitor real-time progress.

Driver Mobile Application: Delivers turn-by-turn navigation, captures proof of delivery, enables communication with dispatch, and provides status updates. Modern applications also support offline operation for areas with poor connectivity.

Analytics and Reporting Platform: Aggregates performance data for continuous improvement, identifying trends, anomalies, and optimization opportunities.

Technology Stack Recommendations

For organizations building custom solutions or evaluating platforms, consider these technology choices:

Backend Services: Node.js or Python provides excellent performance and extensive libraries for optimization algorithms. Go offers superior performance for high-throughput routing calculations. Java remains popular for enterprise integrations.

Routing Algorithms: Open-source libraries like OR-Tools (Google), OSRM (Open Source Routing Machine), and Vroom provide production-ready implementations of advanced routing algorithms, reducing development time and ensuring algorithmic quality.

Database Architecture: PostgreSQL with PostGIS extension excels for geospatial queries. Redis provides fast caching for frequently accessed route data. Time-series databases like InfluxDB efficiently store and query vehicle telematics data.

Mobile Development: React Native enables code sharing between iOS and Android while maintaining native performance. Flutter offers similar benefits with potentially better performance for graphics-intensive applications.

Mapping and Geocoding: Google Maps offers the most comprehensive coverage and accuracy, but at premium pricing. Mapbox and Here provide competitive alternatives with more flexible pricing for high-volume applications.

Want a deeper breakdown of tools and frameworks? Explore the full tech stack for on-demand fuel delivery app development.

Overcoming Common Implementation Challenges

Driver Adoption and Change Management

Technology implementation often fails due to inadequate attention to human factors. Drivers may resist route optimization systems if they perceive them as surveillance tools or threats to their autonomy. Successful implementations:

- Involve drivers early in system selection and configuration, incorporating their practical knowledge of delivery territories

- Emphasize benefits, including reduced driving time, fewer difficult deliveries, and more predictable schedules

- Provide comprehensive training using realistic scenarios and hands-on practice with the mobile interface

- Implement gradually, starting with volunteers or a pilot region, before mandatory rollout

- Create feedback channels allowing drivers to report issues, suggest improvements, and see their input incorporated

Research shows that driver satisfaction with routing technology correlates strongly with implementation success, with well-executed rollouts achieving 85%+ adoption within 60 days.

Handling Real-Time Disruptions

Static routes inevitably encounter disruptions—traffic accidents, vehicle breakdowns, emergency orders, or customer unavailability. Effective systems employ several strategies:

Trigger-Based Recalculation: Automatically recalculate routes when significant events occur, such as delays exceeding 15 minutes, vehicle breakdowns, or high-priority emergency orders. The system should evaluate whether local adjustments suffice or full route reoptimization is warranted.

Rolling Horizon Optimization: Rather than optimizing the entire day’s routes, continuously optimize the next 2-4 hours in detail while maintaining high-level plans for later deliveries. This approach balances stability (drivers aren’t constantly receiving route changes) with adaptability.

Buffer Time Integration: Build explicit buffer time into routes—typically 10-15% of estimated delivery time—to absorb minor delays without cascading effects on subsequent stops.

Driver Override Capabilities: Enable experienced drivers to suggest route modifications when they possess local knowledge the system lacks (construction not yet in traffic databases, preferred customer delivery times not documented in the system).

Measuring ROI and Continuous Improvement

Quantifying the value of route optimization requires comprehensive metrics tracking:

Operational Metrics: Miles driven, fuel consumed, deliveries per vehicle per day, on-time delivery percentage, average time per delivery, vehicle utilization rate.

Financial Metrics: Cost per delivery, fuel cost per mile, maintenance costs, overtime hours, customer acquisition/retention (improved service quality).

Quality Metrics: Customer satisfaction scores, complaint rates, delivery accuracy, damage incidents, and regulatory compliance metrics.

Leading implementations establish dashboards that automatically track these metrics, highlighting trends and anomalies. Monthly reviews compare actual performance against baseline (pre-optimization) and target metrics, identifying specific improvement opportunities.

Machine learning components should also be continuously refined using actual delivery performance data, improving prediction accuracy over time. Systems that learn from real-world outcomes typically achieve an additional 5-10% improvement in route quality within the first year of operation.

Regulatory Compliance and Safety Considerations

Fuel delivery involves heightened safety and regulatory requirements that route optimization systems must respect:

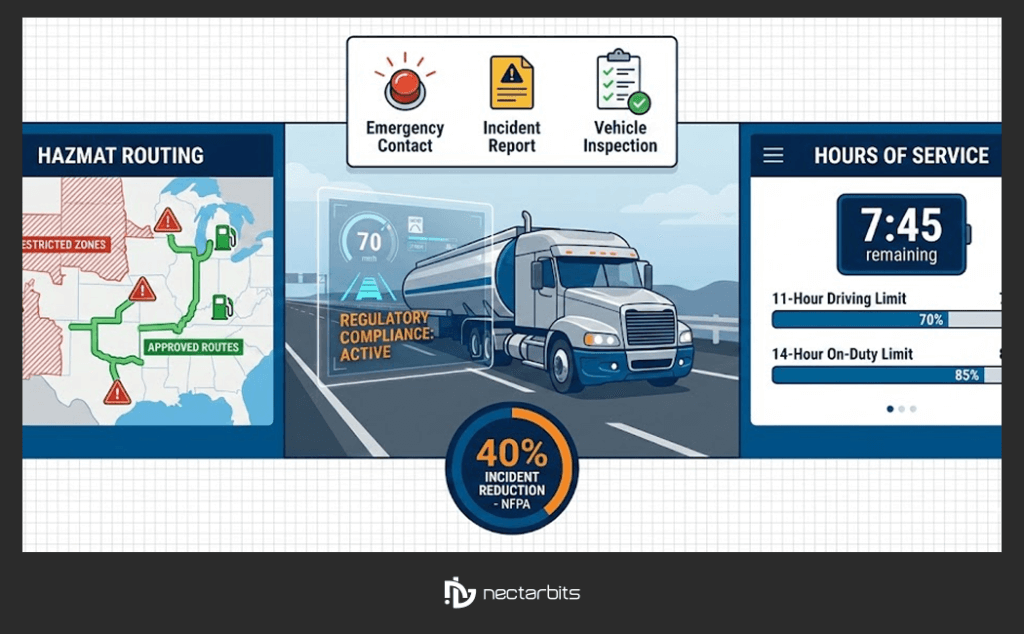

Hazmat Routing Restrictions

Federal and state regulations restrict hazardous materials transport on certain roads. The FMCSA designates specific routes for hazmat transport, and many municipalities impose additional restrictions. Route optimization systems must integrate these restrictions as hard constraints—routes that violate hazmat regulations simply cannot be selected, regardless of efficiency gains.

Hours of Service Compliance

The FMCSA mandates strict limits on driver working hours to prevent fatigue-related accidents. Route optimization must account for:

- 11-hour driving limit per shift

- 14-hour on-duty limit, including non-driving time

- 30-minute break requirement within the first 8 hours

- 60/70-hour weekly limits

Advanced systems integrate with electronic logging devices (ELDs) to track actual hours in real-time, automatically adjusting routes as drivers approach hour limits.

Safety and Emergency Response

Fuel delivery app development should incorporate safety features, including:

- Emergency contact integration: Instant access to hazmat response teams and relevant authorities

- Incident reporting: Streamlined reporting workflows for spills, accidents, or equipment failures

- Vehicle inspection checklists: Digital pre-trip and post-trip inspection processes ensuring vehicle safety

According to NFPA (National Fire Protection Association), proper routing and dispatch procedures reduce fuel delivery incidents by up to 40%, underscoring the safety value of optimized systems that reduce total miles driven and minimize risky maneuvers.

Future Trends in Route Optimization Technology

Artificial Intelligence and Machine Learning

Next-generation systems increasingly leverage AI for:

Demand Forecasting: Predicting future delivery volumes and locations based on historical patterns, seasonality, weather, and economic indicators. This enables proactive fleet positioning and more accurate capacity planning.

Adaptive Learning: Continuously refining route quality based on actual delivery outcomes. Systems learn optimal service times for specific customers, realistic travel speeds for different routes and times of day, and the impact of various factors (weather, events) on delivery efficiency.

Anomaly Detection: Automatically identifying unusual patterns—unexpected delays, abnormal fuel consumption, or unusual delivery sequences—that may indicate problems requiring human investigation.

Electric Vehicle Integration

As fuel delivery companies begin electrifying their fleets, route optimization must account for new constraints:

- Range limitations require careful route planning to ensure vehicles can complete assignments and return to charging locations

- Charging time requirements, which may necessitate mid-route charging stops

- Battery degradation in cold weather affects the practical range

- Charging infrastructure availability constrains where vehicles can operate

Specialized algorithms for electric fleet routing are emerging, balancing traditional routing objectives with energy consumption minimization and charging infrastructure constraints.

Autonomous Delivery Vehicles

While full autonomy remains years away for fuel delivery (due to safety considerations and complex delivery site negotiations), semi-autonomous features are emerging:

- Automated highway driving reduces driver fatigue on long-haul portions of routes

- Assisted parking and positioning at delivery sites

- Automated safety monitoring detects driver fatigue or distraction

Route optimization for mixed human-autonomous fleets represents an emerging challenge, as autonomous vehicles have different capabilities, limitations, and cost structures than human-driven vehicles.

Real-World Case Studies and Implementation Patterns

Regional Fuel Distributor: 40-Vehicle Fleet Optimization

A mid-sized fuel distributor serving commercial clients across three states implemented comprehensive route optimization:

Before Implementation:

- 40-vehicle fleet making 280 deliveries daily

- Manual route planning takes 2-3 hours per day

- Average 165 miles per vehicle per day

- 78% on-time delivery rate

- Frequent overtime for drivers

Technology Approach:

- Cloud-based optimization platform integrated with existing dispatch software

- React Native mobile application for driver navigation and proof-of-delivery

- Integration with a telematics system for real-time vehicle tracking

- 8-week phased implementation starting with 10-vehicle pilot

Results After 6 Months:

- 22% reduction in total miles driven (saving approximately $180,000 annually in fuel costs)

- 92% on-time delivery rate

- 28% increase in deliveries per vehicle

- Route planning time reduced to 20-30 minutes

- Dispatcher capacity freed for customer service improvements

- ROI achieved within 11 months

National Chain: Enterprise-Scale Implementation

A national fuel delivery chain with 800+ vehicles across 15 regions implemented a custom-built route optimization system:

Strategic Drivers:

- Unique competitive requirements around guaranteed delivery windows

- Existing technology team capable of ongoing development

- Long-term cost advantages of a custom solution at an enterprise scale

- Desire for proprietary algorithms providing a competitive advantage

Technology Stack:

- Python-based optimization engine using custom genetic algorithms

- PostgreSQL database with PostGIS for geospatial queries

- React web interface for dispatchers

- React Native mobile application for drivers

- AWS cloud infrastructure with regional failover

- 18-month development and deployment cycle

Implementation Challenges:

- Integration complexity with diverse legacy systems across regions

- Change management across a large, geographically distributed driver workforce

- Data quality issues requiring extensive address database cleanup

- Performance optimization for routing calculations at enterprise scale

Long-term Outcomes:

- 18% reduction in cost per delivery across the enterprise

- Proprietary routing algorithms tailored to specific customer segment needs

- Continuous improvement capability with an in-house development team

- Competitive advantage in time-sensitive delivery segments

These case studies illustrate that both commercial and custom solutions can deliver substantial value, with the optimal choice depending on organizational scale, technical capabilities, competitive requirements, and strategic priorities.

Want to see how on-demand fleet fueling works in the real world? Explore the Filld on-demand fleet fueling case study.

Conclusion: Strategic Roadmap for Implementation

Successful real-time fuel delivery route optimization requires balancing advanced technology with practical execution. Key success factors include:

- Clear Requirements: Define workflows, pain points, and success metrics early, with input from drivers, dispatchers, and operations teams.

- Right Technology Fit: Align solution complexity with fleet size—off-the-shelf tools suit smaller fleets, while large operations may need custom systems.

- Phased Rollout: Start with pilot programs to validate value, refine processes, and reduce implementation risk.

- Continuous Improvement: Treat optimization as an ongoing initiative, using performance data and user feedback to drive refinements.

- Change Management: Adoption matters as much as technology—training and support are critical for success.

As competition and customer expectations rise, intelligent routing is no longer optional. Fuel delivery companies that implement it effectively gain lasting advantages through lower costs, improved service quality, and greater operational agility.

Related Reading:

Want to explore the complete technology ecosystem for fuel delivery operations? Check out our comprehensive guide on Fuel Delivery Dispatch Software, covering everything from order management to customer communication systems.

Frequently Asked Questions:

Most fuel delivery companies see positive ROI within 8–14 months, driven by lower fuel costs, more deliveries per vehicle, and reduced overtime.

Yes. Most modern systems integrate via APIs or pre-built connectors, allowing seamless data exchange without replacing your current dispatch software.

Yes. Advanced systems use real-time re-optimization to quickly reroute the nearest vehicle while minimizing disruption to scheduled deliveries.

You need accurate addresses, vehicle capacity details, delivery time estimates, and order data. Poor data quality can reduce optimization results by up to 50%.